Jyoti World Highlights Role of Engineered Plastics in Supporting Global Water Infrastructure

Company to Showcase Precision Components for Pump Applications at K 2025, Messe Düsseldorf

MUMBAI, MAHARASHTRA, INDIA, April 24, 2025 /EINPresswire.com/ -- As countries around the world face growing water scarcity, aging infrastructure, and pressure to modernize irrigation and utility systems, the demand for advanced, efficient, and sustainable fluid handling components is rising rapidly.

Amid this shift, Jyoti World Private Limited, a contract manufacturer specializing in precision plastic engineering, is making significant contributions to the global pump manufacturing ecosystem. With over 60 years of legacy and an export footprint covering India, the USA, and Europe, Jyoti World is helping OEMs move away from metal and adopt engineered plastic alternatives designed for today’s environmental and performance challenges.

Global Water Challenges Prompt Infrastructure Evolution:

The 21st century is defined by increasing urbanization, rapid climate changes, and a growing need for sustainable water management. Groundwater depletion in developing economies, aging utility systems in industrial nations, and surging demand for smart agricultural practices have all intensified the need for reliable water pumps and fluid movement technologies.

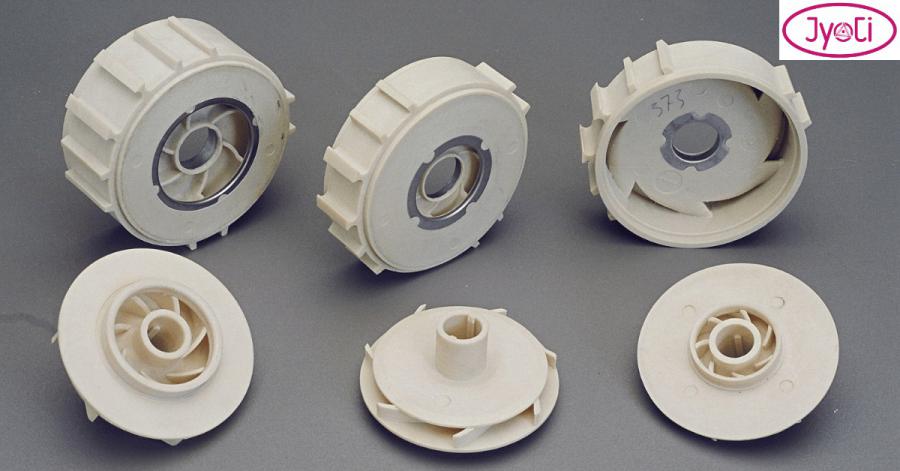

One of the most important innovations supporting this evolution is the shift from metal to plastic—particularly for impellers, diffusers, and pump housings. These components are critical in maintaining flow efficiency, energy performance, and long-term durability of water handling systems.

Plastic components provide corrosion resistance, reduced weight, and lower energy draw, making them ideal for submersible pumps, booster systems, irrigation setups, and municipal infrastructure. This material shift is becoming an industry norm and a necessity, particularly in humid, abrasive, and chemically reactive environments where metal degrades over time.

Engineering Plastics: The New Standard in Pump Components:

Since 1984, Jyoti World has been supplying plastic pump parts to clients across multiple geographies, tailoring its offerings to meet both functional and regulatory requirements. The company’s custom polymer compounding capabilities allow it to deliver materials engineered for:

- High pressure and temperature resistance

- Chemical and mineral exposure in groundwater

- Long operational lifecycles

- Compatibility with international potable water standards including WRAS (UK), KTW (Germany), ACS (France), and NSF (USA)

By aligning with these standards, Jyoti World ensures its components are globally compliant and accepted, making them a preferred choice for OEMs looking to expand their market reach without compromising on performance or certifications.

Scalable Manufacturing Backed by In-House Capabilities:

Jyoti World’s state-of-the-art manufacturing facility, spread across 400,000+ sq. ft. near Vapi, Gujarat, is built to handle the full lifecycle of plastic part production—from material formulation to tool design and high-volume manufacturing. Key capabilities include:

- Injection Molding:

50+ machines ranging from 60T to 1200T, supporting thin-wall, thick-wall, insert, and two-shot molding technologies

- In-House Tool Room:

Advanced CAD/CAM capabilities with Moldflow analysis and tooling designed for confidentiality and precision

- Polymer Compounding:

Custom recipes developed for thermal, mechanical, and environmental specifications

- Post-Molding Solutions:

Including dynamic balancing, ultrasonic welding, CNC plastic machining, pad/foil printing, and clean assembly processes

These capabilities support applications where dimensional accuracy, repeatability, and material integrity are critical—particularly in impellers and diffusers up to 12 inches, widely used in agricultural, commercial, and municipal pump systems.

Reverse Engineering and Legacy Support

A significant challenge many OEMs face is component obsolescence—particularly for pumps that have been in operation for decades. Jyoti World addresses this challenge through reverse engineering services, helping customers extend the lifespan of their equipment by recreating discontinued or hard-to-source parts with new materials and improved performance.

Combined with a strong knowledge base in metal-to-plastic conversion, the company enables clients to move from traditional designs to next-generation solutions without compromising functionality or system fitment.

Aligning with National and Global Development Goals:

India’s push for 100 Smart Cities and global movements like the UN Sustainable Development Goals (SDGs) call for more efficient infrastructure, clean water access, and sustainable urban planning. Pumps and fluid handling systems are at the heart of this transformation.

Jyoti World’s components play a key role in enabling:

- Smart irrigation for water conservation in agriculture

- Domestic water supply and drainage systems in smart cities

- Industrial cooling and waste water management

- Off-grid and solar-powered pump applications

By reducing the energy load and increasing component longevity, engineered plastics contribute directly to cost savings, lower maintenance needs, and better lifecycle outcomes.

Jyoti World to Exhibit at K 2025 in Düsseldorf:

To support global knowledge sharing and showcase its innovations, Jyoti World will be exhibiting at K 2025, the world’s largest trade fair for the plastics and rubber industries, to be held from October 8–15, 2025, at Messe Düsseldorf, Germany.

Visitors are invited to Booth BH 25 in Hall 8b, where the company will display a selection of its precision-engineered components for fluid engineering, submersible pumps, and plastic-to-metal conversion programs.

Technical experts and business development leaders from Jyoti World will be available to discuss partnership opportunities, understand application-specific challenges, and explore how custom polymer and component design can help clients meet their cost, quality, and regulatory goals.

The Road Ahead:

With its continuous investment in infrastructure, tooling, R&D, and international certifications, Jyoti World is positioned to support OEMs through every stage of the product journey—from concept to mass production.

The company’s integrated services, including prototyping, pilot runs, validation testing, and export packaging, ensure faster time to market and streamlined global supply chain support. With a growing focus on sustainability, Jyoti World is also exploring recyclable polymers and low-carbon production techniques to align with evolving industry mandates.

About Jyoti World Private Limited:

Founded in 1959, Jyoti World Private Limited is a 360° contract manufacturing company specializing in plastic injection molding, extrusion, polymer compounding, and in-house mold/tool making. With domain expertise across fluid engineering, EVs, telecommunications, electronics, and white goods, the company serves Fortune 500 clients and mid-sized OEMs with export-ready solutions that emphasize precision, confidentiality, and scalability.

Jyoti World’s infrastructure is ISO 9001:2015 and ISO 14001:2015 certified, and its manufacturing plant is equipped to deliver batch flexibility, tool security, and engineering support for complex plastic applications.

Poorwal Oak

Jyoti World Private Limited

+ +918422869122

email us here

Visit us on social media:

LinkedIn

Corporate Video of Jyoti World Private Limited

Distribution channels: Agriculture, Farming & Forestry Industry, Consumer Goods, Energy Industry, Manufacturing, Waste Management

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release