Geomega and Rio Tinto provide update on bauxite residue valorization pilot

/EIN News/ -- MONTREAL, April 16, 2025 (GLOBE NEWSWIRE) -- Geomega Resources Inc. (“Geomega” or the “Corporation”) (TSX.V: GMA) is pleased to provide an update on the bauxite residue valorization activities, done in collaboration with Rio Tinto.

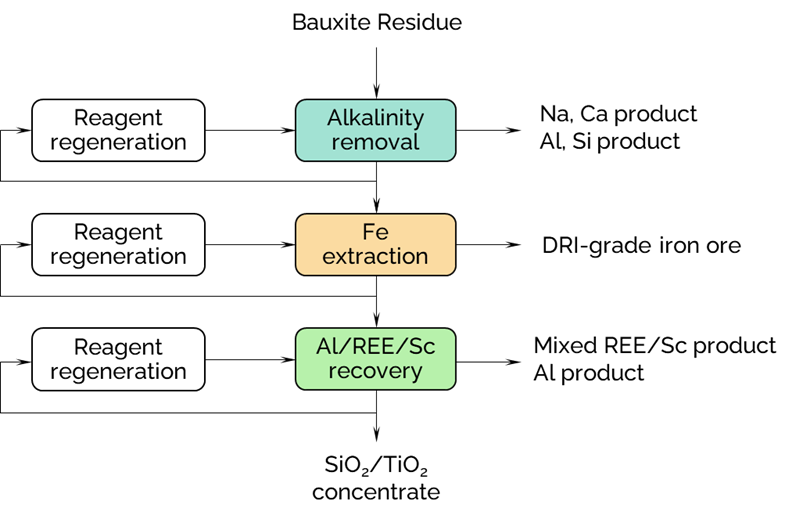

Since the launch of the pilot project in March 2022 (see press release from March 31, 2022), Geomega has continued to develop and further derisk its innovative bauxite residue valorization technology. The technology is divided into three consecutive circuits which are being tested and scaled up individually. A refinery client might license Circuit 1, Circuits 1 and 2 or the complete package of Circuits 1, 2 and 3 depending on the grades of the various metals found in its bauxite residues and the corporate objectives.

Circuit 1 (C1) focuses on alkalinity removal and production of several important offtake streams such as sodium, calcium, aluminium and silica products. This circuit is responsible for 10% to 30% of waste volume reduction.

Circuit 2 (C2) deals with iron extraction and removal. One potential high value and critical product is DRI (Direct Reduced Iron) grade ore material, a high-purity iron feedstock that enables lower-carbon steelmaking. Circuits 1 and 2 are responsible for more than 70% of cumulative waste volume reduction.

Circuit 3 (C3) deals with the remaining high value metals. Geomega is currently developing a cost-efficient circuit to extract and purify a rare earths (REE) concentrate, and a titanium concentrate while regenerating and recycling the reagent. Other potential products in Circuit 3 include scandium, gallium, alumina, and silica.

Each circuit has its own reagent recycling, resulting in minimal effluents and no additional hazardous waste being produced by the process. One of the main advantages of the technology is that more than 95% of the main reagents for C1 and C2 are being recycled, having a major impact on the operating costs of the process. Figure 1 below summarizes the bauxite residue valorization technology.

Figure 1: Bauxite residue valorization process overview

Over the last three years, many rounds of bench scale and then pilot scale testwork were completed to validate the key process parameters, and to produce samples throughout the process for product validation and optimization. Rio Tinto provided Geomega with a specific range of parameters for purities and particle sizes which have now been successfully confirmed and validated by Rio Tinto’s team.

Pilot testwork has been completed for C1 and C2 which allowed Geomega to produce a representative sample of the residue needed for piloting of C3. That work is planned for 2025. Geomega and Rio Tinto have now signed an extension to their collaboration agreement to continue the work on C3 as part of the project that was launched in March 2022.

In parallel, Geomega and Rio Tinto are planning the next phase for C1 and C2 based on the positive results received to date. More details on the next steps will be provided once an agreement is finalized for this next phase.

“Geomega’s research, engineering and the technical team have done an amazing job over the last 3 years to bring our bauxite residue valorization technology from bench scale to a successful pilot scale operation. The improvements along the way made the technology more robust and flexible while paving the way for an economical solution. The aluminum industry needs such a technology to improve its long term social and environmental impacts. On the other hand, the world needs a large and sustainable supply of critical metals that are found in these bauxite residues. Geomega’s technology unlocks both these opportunities while bringing potential long-term returns to the Corporation in the form of royalties.” commented Kiril Mugerman, President & CEO of Geomega.

“Research partnerships play a key role in our strategy to reduce and valorize bauxite residues from our responsible production of aluminium. Rio Tinto is pleased with the pilot results of our collaboration with Geomega and we look forward to supporting the next phase of this innovative partnership”, added Josette Ross, General Manager of Rio Tinto’s Arvida Research and Development Center.

About Geomega (www.geomega.ca)

Geomega develops innovative technologies for extraction and separation of rare earth elements and other critical metals essential for a sustainable future. Geomega works with various feed streams to apply its technologies to waste valorization. This includes NdFeB magnet recycling, bauxite residue and sulphide tailings processing. Geomega’s strategy revolves around gradually de-risking its innovative technology and delivering cashflow and return value to shareholders while working directly with the main players in their respective industries.

As its technologies are demonstrated on larger scales, Geomega is committed to work with major partners to help extract value from mining feeds, tailings and other industrial residues which contain rare earths and other critical metals. Irrespective of the metal or the source, Geomega adopts a consistent approach to reduce the environmental impact and to contribute to lowering greenhouse gases emissions through recycling the major reagents in the process.

Geomega also owns the Montviel rare earth carbonatite deposit, the largest 43-101 bastnaesite resource estimate in North America and holds over 16.8M shares, representing approximately 13% of the issued and outstanding shares, of Kintavar Exploration Inc. (KTR.V), a mineral exploration company that is exploring for copper projects in Quebec, Canada.

For further information, please contact:

| Kiril Mugerman |

| President and CEO |

| Geomega |

| 514-223-1449 ext. 3 |

|

kmugerman@geomega.ca Nancy Thompson Vorticom Public Relations 212-532-2208 nancyt@vorticom.com Twitter: @Geomega_REE |

Cautions Regarding Forward-Looking Statements

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This news release contains statements that may constitute “forward-looking information” or “forward-looking statements” within the meaning of applicable Canadian securities legislation. Forward-looking information and statements may include, among others, statements regarding future plans, costs, objectives or performance of the Corporation, or the assumptions underlying any of the foregoing. In this news release, words such as “may”, “would”, “could”, “will”, “likely”, “believe”, “expect”, “anticipate”, “intend”, “plan”, “estimate” “target” and similar words and the negative form thereof are used to identify forward-looking statements. Forward-looking statements should not be read as guarantees of future performance or results, and will not necessarily be accurate indications of whether, or the times at or by which, such future performance will be achieved. No assurance can be given that any events anticipated by the forward-looking information will transpire or occur, including as regards the commercialization of any of the technology referred to above, or if any of them do so, what benefits the Corporation will derive. Forward-looking statements and information are based on information available at the time and/or management's good-faith belief with respect to future events and are subject to known or unknown risks, uncertainties, assumptions and other unpredictable factors, many of which are beyond the Corporation’s control. These risks, uncertainties and assumptions include, but are not limited to, those described under “Risk Factors” in the Corporation’s annual management’s discussion and analysis for the fiscal year ended May 31, 2024, which is available on SEDAR at www.sedar.com; they could cause actual events or results to differ materially from those projected in any forward-looking statements. The Corporation does not intend, nor does the Corporation undertake any obligation, to update or revise any forward-looking information or statements contained in this news release to reflect subsequent information, events or circumstances or otherwise, except if required by applicable laws.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/062e73bb-1b32-4cf2-ac1d-68b670e60b2f

Distribution channels: Media, Advertising & PR, Mining Industry ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release