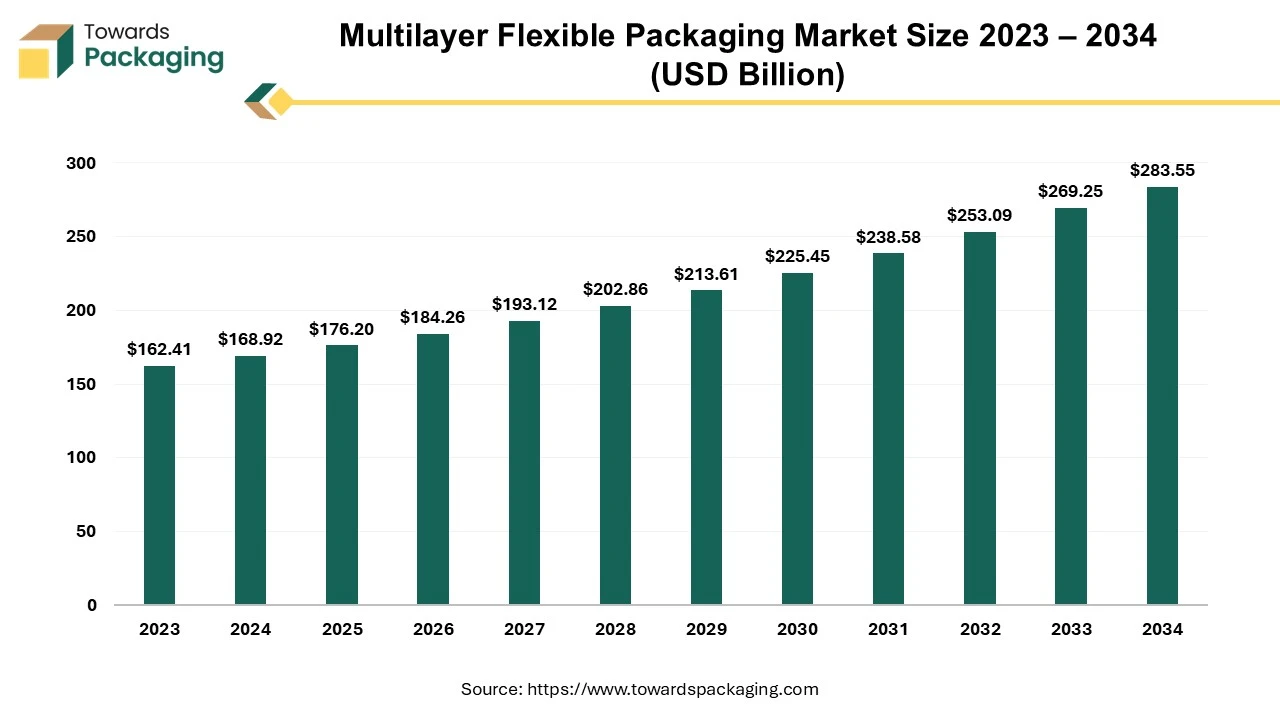

Multilayer Flexible Packaging Market to Climb USD 283.55 Bn by 2034, says Packaging Analysts

According to towards packaging experts, the multilayer flexible packaging market size stood at USD 168.92 billion in 2024 and is predicted to exceed USD 283.55 billion by 2034, experiencing a CAGR of 5.32% from 2024 to 2034.

/EIN News/ -- Ottawa, April 15, 2025 (GLOBE NEWSWIRE) -- The multilayer flexible packaging market size to record USD 176.20 billion in 2025 and is projected to grow beyond USD 283.55 billion by 2034, a study published by Towards Packaging a sister firm of Precedence Research. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and collaboration to develop new technology for multilayer flexible packaging, which has estimated to drive the growth of the multilayer flexible packaging market in the near future.

Get All the Details in Our Solutions – Download Brochure: https://www.towardspackaging.com/download-brochure/5455

Market Overview:

In order to build a container with better barrier and functional qualities, multi-layer flexible packaging uses many layers of flexible materials, such as films and foils. Products for the food and beverage, personal care, pharmaceutical, and home industries all make substantial use of this kind of packaging. A number of factors are driving the multi-layer flexible packaging market's significant expansion. Numerous reasons, including the growing demand for lightweight and convenient packaging solutions, consumers' preference for items with longer shelf lives, and the expansion of the e-commerce sector, are propelling the market's rise.

Major Key Trends in Multilayer Flexible Packaging Market:

-

Sustainability Initiatives

Huge push for compostable, recyclable, and bio-based multilayer films. Traditionally, multilayer packaging is hard to recycle (because of mixed materials), but various brands are developing mono-material solutions (like all-polypropylene or all-polyethylene layers) that still provide barrier properties but are easier to recycle.

-

Lightweighting

Minimizing the thickness and weight of packaging without compromising performance. Cuts costs, lowers carbon footprint, and meets sustainability goal

-

High-Performance Barrier Films

The high demand for superior barrier properties to extend shelf life, especially in food, pharma, and personal care. Technologies include EVOH, nanocoatings, and metalized films to protect against oxygen, moisture, and light.

-

Digital Printing & Customization

Brands want high-quality, customized packaging with vibrant colors and fast turnaround. Digital printing allows shorter runs, variable data printing (for promotions, QR codes), and personalisation.

-

Smart & Functional Features

Integration of intelligent elements like freshness indicators, QR codes for traceability, and tamper-evidence. The multilayer flexible packaging us useful in pharma, food, and high-value consumer goods.

-

Expansion of Clean-Label Packaging

Transparent or “see-through” multilayer designs that showcase the product inside. The multilayer packaging appeals to health-conscious and eco-conscious consumers.

-

Expanding Food & Beverage Demand

Especially for ready-to-eat meals, snacks, and frozen foods, which demand durable, multilayer flexible films to maintain freshness and shelf life.

-

Regulatory Pressures Driving Innovation

Governments and industry bodies pushing for Extended Producer Responsibility (EPR). The manufacturers are innovating to meet new packaging waste directives.

Limitations & Challenges in Multilayer Flexible Packaging Market:

-

Challenges in Recycling Multilayer Product

Traditional multilayer films are made of different materials (plastic + foil + paper, etc.) laminated together. Multiple layers are hard to separate, making them difficult to recycle with existing infrastructure. Rising pressure from governments and consumers for recyclability is a major restraint.

-

Complex Manufacturing Processes

Multilayer flexible packaging requires specialized machinery and expertise for lamination, extrusion, and printing. This complexity can limit scalability and increase lead times.

-

Growing Alternatives

Rise of mono-material films and rigid packaging alternatives that are easier to recycle. Also, materials like aluminum, glass, and paper-based solutions are gaining popularity for sustainability reasons.

If there's anything you'd like to ask, feel free to get in touch with us @ sales@towardspackaging.com

Increase in Demand & Boom in Ecommerce: Market’s Largest Opportunity

Asia-Pacific, Latin America, and Africa region are observing demand for medicines, packaged foods, and personal care products. Rapid urbanization and increasing disposable incomes are driving consumption of products that rely on flexible packaging. Multilayer flexible packaging provides tamper evidence, puncture resistance, and light weight, making it ideal for shipping. Integration of freshness indicators, track & trace, temperature-sensitive inks, and QR codes. The multi-layers packaging assists brands add value and consumers ensure product safety and authenticity. Hence, rising demand for multilayer flexible packaging has driven the growth of the market over the forecast period.

Regional Analysis:

North America’s Large Consumer Base to Promote Dominance

North America region held the largest share of the multilayer flexible packaging market in 2024, owing to large food and beverage industry in the region. North America has strict food safety regulations (FDA, CFIA), making high-barrier multilayer packaging essential for compliance. The U.S. and Canada have cutting-edge production capabilities for multilayer extrusion, lamination, and printing. North America has high demand for packaged foods, snacks, ready-to-eat meals, frozen foods, and beverages. North American companies are leading in developing recyclable or bio-based multilayer materials.

- For instance, in February 2023, Northwest Frozen LLC and Preferred Packaging, a branch of C-P Flexible Packaging, have successfully partnered to create and introduce a new line of prepared, chilled meals with longer shelf lives for retail distribution. Among the new products is Crocchi, a frozen croissant-shaped gnocchi noodle product that was selected as one of Oprah's Favorite Things for the 2022 fall season.

- After being cryofrozen, the pasta is placed in containers with a modified environment and strong barrier. High-quality frozen meals are also produced by Northwest Frozen LLC as private label products for the biggest supermarket chain in the U.S. The Affirm M line of multi-layer packaging materials, which includes the exclusive C-P Film, offers the finest performance in its class. T

The industry's largest sealing window is offered by the Affirm M film. Customers don't need a knife or scissors because they can remove the lidding film off the tray. Additional uses for Affirm M lidding films include packaging and high-pressure pasteurization of fresh, all-natural goods.

Asia Large Agricultural Export To Support the Market’s Expansion

Asia Pacific region is seen to grow at the fastest rate in the multilayer flexible packaging market during the forecast period. Massive urbanization across China, India, Southeast Asia. Growing middle-class population with increasing disposable incomes leads to higher demand for packaged foods, beverages, and personal care products. Asia Pacific is a huge market for convenience snacks, dairy, foods, instant noodles, and beverages. Asia Pacific region has low-cost labor and well-developed manufacturing hubs.

Major Trends in Flexible Packaging Sector in Asian Countries:

- Governments in Asia Pacific region are starting to implement regulations on packaging waste. Countries like China, India, Thailand, and Vietnam are major exporters of agricultural products, which require durable multilayer flexible packaging for extended shelf life.

- The key players operating in the Asia Pacific region are significantly investments in modernizing production technologies and advanced printing techniques.

- Major multinational brands are investing in local production in India facilities to meet regional demand efficiently. Also partnering with local packaging companies in Asia Pacific region to innovate sustainable multilayer solutions.

- The key players operating in the Asia Pacific region are expanding within the region for providing packaging facilities, which has estimated to drive the growth of the flexible packaging market in the near future.

For instance, in April 2025, Nelipak Corporation, a company focused on manufacturing packaging solutions, revealed the introduction of the its manufacturing facilities in Asia Pacific region on direct basis by adopting inorganic growth strategies like partnership.

A wide variety of specially created sterile-barrier packaging options are available in the Nelipak medical packaging product linev. Nelipak offers a range of flexible packaging products, including as bags, pouches, die-cut sheets and lids, and coated roll-stock.

These products combine Nelipak heat-seal coating technology (Nelipak CR27 and Nelipak SBP2000 coatings; Nelipak PS-series coated papers) with a variety of material substrates (Tyvek, medical papers, films, and foil-laminates).

Following Nelipak's 2019 acquisition of Bemis Healthcare Packaging Europe, several well-known flexible medical packaging options were added to the Nelipak Healthcarè Packaging portfolio. Furthermore, medical tray sealing machines and rigid thermoformed trays are part of Nelipak's medical packaging solutions.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Segment Outlook

Material Insight

The plastics segment dominated the multilayer flexible packaging market with the largest share in 2024. Plastics like polyethylene (PE), EVOH, polypropylene (PP), and polyamide (nylon) offer strong barriers against moisture, gases, oxygen and light. These properties are essential for keeping food fresh, protecting pharmaceuticals, and preserving sensitive products. Plastics can be easily layered and combined to develop films with specific function: tear resistance, puncture resistance, resealability, etc. Customization is much easier and cost-effective with plastics. Plastics are inherently lightweight, minimizing transportation costs and carbon footprint.

The paper segment is anticipated to witness lucrative growth during the forecast period. Paper is recyclable, renewable, and biodegradable, making it very attractive to eco-conscious consumers and brands. The multilayer paper packaging helps brands meet sustainability goals and enhance public image. Paper gives organic, natural and premium feel, which appeals to consumers seeking eco-friendly or artisanal products. Paper materials has excellent print surfaces, allowing for vibrant colors and tactile finishes (like embossing or matte textures). Paper is being combined with thin functional layers (like water-based barriers or bio-based coatings) to improve moisture, oxygen and grease resistance. Paper materials are lightweight which helps in reducing shipping costs.

Product Insight

The pouches and sachets segment accounted for the largest multilayer flexible packaging market share in 2024. The pouches and sachets are easy to open, reseal and carry. Multilayer pouches and sachets offer strong protection against oxygen, moisture, UV light and contaminants. The pouches and sachets enables for full-surface printing and branding, enhancing visibility at point-of-sale. Rising development of recyclable mono-material pouches and bio-based materials.

The bags segment is anticipated to show the fastest growth during the forecast period. Bags can hold a wide range of product volumes, from small quantities to bulk goods. The bags are suitable for powders, pet food, grains, fertilizers, chemicals, snacks, frozen foods, among others. Multilayer films give bags the ability to withstand heavy weights and rough handling during shipping and storage. Bags are less expensive compared to rigid containers, especially for large volumes.

Layer Structure Insight

The 7 layers segment accounted for a significant share of the market in 2024. 7 layers allow for combining multiple materials to offer superior barriers against oxygen, light, moisture and contaminants. Multi-material layering improves puncture resistance, durability and tear strength. Using 7 layers assists to minimize the thickness of expensive materials (like EVOH) by distributing them optimally. 7-layer films are ideal for vacuum packaging, thermoforming, modified atmosphere packaging

The 5 layers segment is anticipated to grow with the highest CAGR in the market during the studied years. 5 layers allow manufacturers to combine materials smartly without overcomplicating the structure. The 5 layers multilayer flexible packaging provides better performance than 3-layer structures, but still cheaper and simpler than 7-layer designs. 5-layer structures give good flexibility, puncture resistance and durability with minimal efforts.

End-Use Insights

The food and beverages segment registered its dominance over the global multilayer flexible packaging market in 2024. Food and beverages need protection from light, oxygen, moisture, and contamination. Multilayer flexible packaging provides excellent barrier properties that extend shelf life and preserve flavor, freshness, and nutrients. Multilayer flexible packaging ensures tamper-evidence and contamination prevention. Brands in food & beverage are moving toward lightweight, recyclable, and eco-friendly multilayer formats. Flexible packaging offers durability and protection during shipping, minimizing damage and leakage. Multilayer flexible packaging reduces material usage while still providing strong protection.

The pharmaceuticals segment is projected to expand rapidly in the multilayer flexible packaging market in the coming years. Medicines need protection from moisture, oxygen, UV light, and contaminants. Multilayer flexible packaging combines different materials (like EVOH, aluminum foil, or nylon) to create high-barrier environments that extend the shelf life of sensitive drugs. The pharmaceutical industry is highly regulated. Multilayer packaging meets global standards for child-resistance, tamper-evidence, anti-counterfeiting, and hygiene.

Flexible packaging minimizes shipping weight and volume compared to glass or rigid plastic containers. Growth of online pharmacies is pushing demand for durable, protective, and tamper-proof packaging for shipping. Pharma companies are exploring sustainable and recyclable multilayer flexible solutions to minimize environmental footprint while maintaining protection.

More Insights in Towards Packaging:

- U.S. Personalised Packaging Market Performance, Trends and Strategic Recommendations: https://www.towardspackaging.com/insights/us-personalised-packaging-market-sizing

- U.S. Food Storage Containers Market Dynamics, Competitive Forces & Strategic Pathways: https://www.towardspackaging.com/insights/us-food-storage-containers-market-sizing

- U.S. Custom Cardboard Boxes Market Research Insight: Industry Insights, Trends and Forecast: https://www.towardspackaging.com/insights/u-s-custom-cardboard-boxes-market

- Sterile Medical Paper Packaging Market Strategic Growth, Innovation & Investment Trends: https://www.towardspackaging.com/insights/sterile-medical-paper-packaging-market-sizing

- Automotive Packaging Market Trends, Disruptors & Competitive Strategy: https://www.towardspackaging.com/insights/automotive-packaging-market

- Food and Beverage Packaging Materials Market Key Business Drivers & Industry Forecast: https://www.towardspackaging.com/insights/food-and-beverage-packaging-materials-market-sizing

- Antimicrobial Packaging Market Research Insight: Industry Insights, Trends and Forecast: https://www.towardspackaging.com/insights/antimicrobial-packaging-market

- Australia Vacuum Sealer Bags Market Key Business Drivers & Industry Forecast: https://www.towardspackaging.com/insights/australia-vacuum-sealer-bags-market-sizing

- Active Packaging Market Growth, Innovation & Investment Trends: https://www.towardspackaging.com/insights/active-packaging-market

- Edible Packaging Market Research Insight: Industry Insights, Trends and Forecast: https://www.towardspackaging.com/insights/edible-packaging-market

Recent Breakthroughs in Global Multilayer Flexible Packaging Market:

- In April 2025, Sonoco Products Company, a world pioneer in high-value sustainable packaging, has sold its Thermoformed & Flexibles Packaging division (TFP) to TOPPAN Holdings Inc. This transaction is extremely complimentary, bringing together the technical know-how and production capacity of the TOPPAN Group's worldwide packaging business with the strong sales network, clientele, and solution development skills of Sonoco's TP business.

- In March 2025, Brawny Bear, a firm that specializes in date-based nutritional food products, has announced a new partnership with Pakka Limited, which is well-known for its compostable packaging solutions. As a result of this collaboration, Date Energy Bars were introduced; they are noteworthy for being the first energy bars in India with flexible, compostable packaging. Brawny Bear's Date Energy Bars are packaged in a novel, flexible, compostable container by Pakka Limited. This innovation addresses the growing problem of packaging waste in India in addition to providing a nutritious snack option.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results—schedule a call today: https://www.towardspackaging.com/schedule-meeting

Global Multilayer Flexible Packaging Market Players

- Amcor Plc

- Mondi Group

- Sealed Air Corporation

- Berry Global Inc.

- Pakka Limited

- Huhtamäki Oyj

- Coveris Holdings S.A.

- Constantia Flexibles

- ProAmpac

- UFlex Ltd.

- Smurfit Kappa Group

- Aptar CSP Technologies

- Clondalkin Group

- Glenroy Inc.

- Winpak Ltd.

- Transcontinental Inc.

Global Multilayer Flexible Packaging Market

By Material

- Plastics

- Paper

- Aluminum Foil

By Product

- Pouches and Sachets

- Bags

- Wrapping Films

- Laminates

- Others

By Layer Structure

- 3 Layers

- 5 Layers

- 7 Layers

- More than 7 Layers

By End-Use

- Food and Beverages

- Pharmaceuticals

- Cosmetics and Personal Care

- Homecare

- Electricals and Electronics

- Others

By Region

-

North America

- U.S.

- Canada

-

Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

-

Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

-

Latin America

- Brazil

- Mexico

- Argentina

-

Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Invest in Premium Global Insights @ https://www.towardspackaging.com/price/5455

If you have any questions, please feel free to contact us at sales@towardspackaging.com

About Us

Towards Packaging is a leading global consulting firm specializing in providing comprehensive and strategic research solutions. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations. We stay abreast of the latest industry trends and emerging markets to provide our clients with an unrivalled understanding of their respective sectors. We adhere to rigorous research methodologies, combining primary and secondary research to ensure accuracy and reliability. Our data-driven approach and advanced analytics enable us to unearth actionable insights and make informed recommendations. We are committed to delivering excellence in all our endeavours. Our dedication to quality and continuous improvement has earned us the trust and loyalty of clients worldwide.

Our Trusted Data Partners:

Precedence Research | Statifacts |Towards Automotive | Towards Healthcare | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire

For Latest Update Follow Us: https://www.linkedin.com/company/towards-packaging/

Distribution channels: Consumer Goods ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release